MasterTrak | Applications | Overview

| Resources | Related

Links | About MRA | Contact

Us

|

|

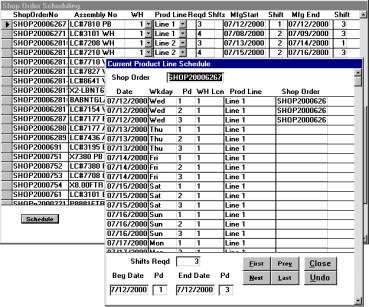

The MasterTrak© Manufacturing Control

application is designed to provide the Distributor and Manufacturer with a

powerful tool to manage and control job shop manufacturing and assembly.† The application provides for multi-level

bill of material processing, creation of Shop Orders from a bill of material,

creating new assemblies and bills of material from a Job Shop estimate, and the

creation of Inventory Requisitions from Shop Orders.† Production plans can be created to identify the required

production necessary for the planning horizon and the various jobs may be

scheduled, using drag and drop methods, into the production areas based on the

date required.

The

Manufacturing control application supports Material

Requirements Planning (MRP) and the implementation of Just-In-Time inventory.† The

MRP report may be printed for scheduled shop orders or may be printed for a

given production plan.

In association

with the MasterTrak Inventory

application, the† Manufacturing Control

application is† barcode enabled to allow for the use of a portable reader or

readers to assist in the release of material to work in process and receipt of

goods to Finished Goods Inventory.

General Capabilities

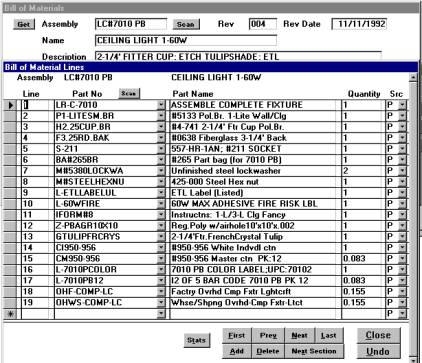

Bill

of Materials (BOM)††††††††††††††††††††††† Multilevel

BOM Processing††††††††††††††††† Multi-level

BOM costing

††††††††††† Shop Order processing†††††††††††††††††††††††† Multiple releases to

WIP†††††††††††††††††††††† Material

Requirements

††††††††††† Requisitioning to WIP†††††††††††††††††††††††††† Multiple Production

Warehouses†††††††††† Receipt of Finished

Goods

Planning

††††††††††† Multiple Production Plans†††††††††††††††††††† BOM supports Labor/Equip ††††††††††††††† Where Used Parts

††††††††††† Job Shop Estimating†††††††††††††††††††††††††††† Production Line

Scheduling†††††††††††††††††† Just-In-Time

Inventory

††††††††††† Copy Bill Utility††††††††††††††††††††††††††††††††††† Replace Part on all BOMís

Master Files

††††††††††† Bill of Material††††††††††††††††††††††††††††††††††††† Shop

Orders††††††††††††††††††††††††††††††††††††††† Master

Shop Orders

††††††††††† Production Lines†††††††††††††††††††††††††††††††††† Labor Rates†††††††††††††††††††††††††††††††††††††††† Production

Machines

††††††††††† Job Shop Estimates

Reports

|

|

††††††††††† ††††††††††††††††††††††††††††††††††† One

Level

Bill of Material† ††††††††††† Indented

††††††††††† ††††††††††††††††††††††††††††††††††† With/without

cost

††††††††††† Master Shop Order

††††††††††† Where Used

††††††††††† Requisitions from Shop Order

Requirements from Shop Orders

††††††††††† Requirements from Plan

††††††††††† Open Shop Orders

††††††††††† Purchase Orders from Shop Order

†††††††††††